Nucleating Agent

Polymer Crystallization

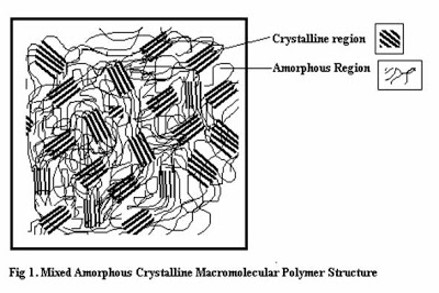

Polymer crystallization is a polymer-chain-alignment process, and in the process, the polymer chains fold together to form ordered regions, such regions as lamellae. Lamellae can be stacked into a larger spherical structure called . The proportion of crystallized area in the whole structure is called Crystallinity, and it is normal 10% to 80%. The difference in crystallinity decides the optical, mechanical, thermal and chemical properties of polymeric materials.

Nucleation

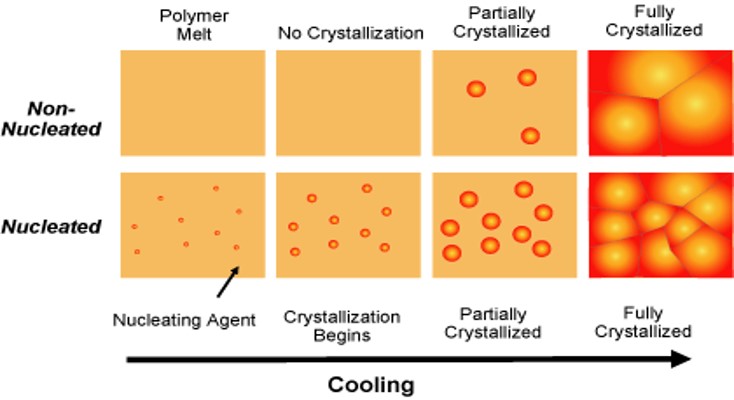

Crystallization happens by cooling down from the melting polymer, but also by mechanical stretching or solvent evaporation. In the process of crystallization, the existence of additives or impurities strongly affects the speed of process and the size of Spherulite. Those additives or impurities act as nuclei and crystallization occurs as heterogeneous nucleation. Therefore, nucleating agent is an additive who promotes crystallization or increases crystallinity, giving polymer different mechanical, chemical and optical properties.

Application of Nucleating Agent

The application of nucleating agents has become more and more significant in recent years. Especially as an additive to modified Polypropylene (PP), nucleating agents can greatly increase rigidity and transparency of Polypropylene (PP) products, which can replace existing high-cost plastic, at the same time, retain its original properties, such as temperature resistance and high plasticity. They are now applied by the mainstream market. Besides, nucleating agents can also be added into Polyamide (PA / Nylon) and Polyethylene Terephthalate (PET), in order to speed up the crystallization and improve the production rate.

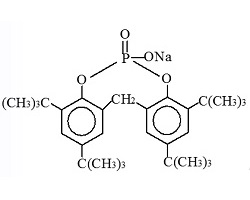

As a highly efficient nucleating & clarifying agent for Polypropylene, PET, PBT and polyamides, which provides excellent transparency and improved mechanical properties such as flexural modulus, crystallization temperatures, HDT and surface hardness in semi-crystalline polymers. It also has excellent extraction resistance and no plate-out, exudation or odor during processing.

| CAS No | 85209-91-2 |

| Appearance | White powder |

| Melting Point | >400℃ |

| Loss on Drying | 0.25% max. |

As a highly efficient nucleating agent for polypropylene, PET, PBT and polyamide.